Why use mobile robotics in cell therapy manufacturing?

Meet the IMRs

Cellular Origins is solving the problem of manufacturing cell therapies at scale by using mobile robotics, AI and proven technology, to enable wider patient access to lifesaving treatments.

To date, commercial manufacturing of these therapies remains a challenge. Yet, if we want to achieve wider patient access to treatments, industrialisation is the only route forward. Constellation is a highly flexible, mobile robotic platform which integrates cell therapy developers’ existing tools and processes.

Why use mobile robots in cell therapy manufacturing?

The challenge of fixed robotics

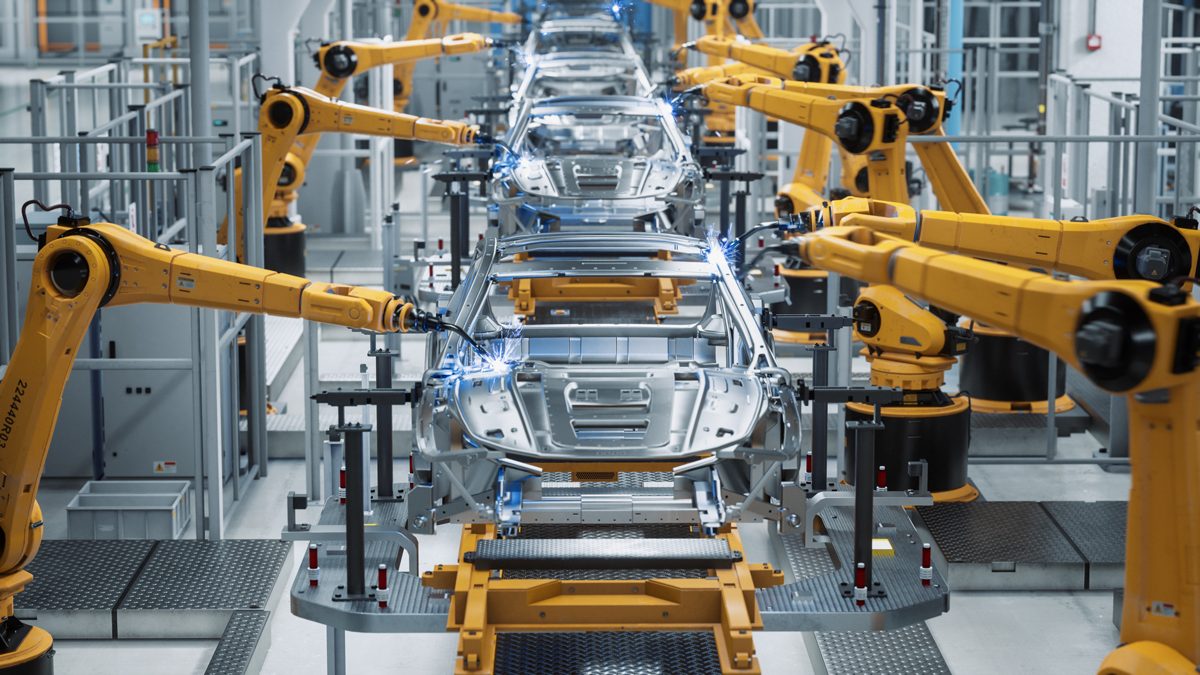

Linear assembly lines incorporating fixed robots have been the norm in manufacturing for decades. But, even rail-bound robots can quickly become bottlenecks. Industries such as automotive and silicon fabrication are now adopting mobile robots to enable a dynamic, modular approach, which adapts in real time.

Manufacturing cell therapies requires a similar approach – one that allows adaptability, and modularity; not rigid, fixed processes.

Our solution takes a factory-first approach, combining modular, and space-efficient facility design with Integrated Mobile Robots (IMRs), creating a truly de-risked manufacturing ecosystem.

Illustration of traditional linear manufacturing approach in the automotive industry

Mobile robotics for ultimate flexibility

IMRs unlock the full benefits of modular manufacturing. They integrate seamlessly with partner technologies, fully automating existing processes without redevelopment.

Because they aren’t tied to fixed tracks or pods, IMRs adapt to any facility layout, scaling easily without significant structural changes.

This modularity keeps facilities running with minimal risk. If one robot fails, another takes its place, keeping high-value tools operational around the clock. IMRs can also be swapped out quickly, avoiding downtime and redundancy. Futureproofed flexibility means you can upgrade your technology without costly interruptions, keeping facilities productive as needs evolve. The design also supports safe human–robot collaboration. Operators can work alongside IMRs with easy access for cleaning and maintenance, keeping GMP compliance simple. With this flexibility, workflows remain dynamic and facilities can evolve without disruption.

Cellular Origins’ IMRs in action

Conclusion

Our approach accelerates time-to-market, reduces risk, and enables the reliable production of hundreds of thousands of doses of transformative therapies.

We are the only company offering this level of flexibility to scale — seamlessly integrating with your existing tools and workflows. This is the low-risk route to scale with fewer errors, lower costs, and a faster return on investment.

Constellation

Constellation is a fully automated, mobile robotic platform enabling seamless scale-up from clinical to commercial cell therapy manufacturing. It integrates modular, proven third-party instruments and automates all critical GMP steps, with a unified digital layer for real-time monitoring and full traceability. By scaling only when needed, it reduces regulatory risk and labour reliance. We also support facility design and strategy to help developers confidently industrialise manufacturing.